Products for PCB’s industry

Process for the inner layers oxidation

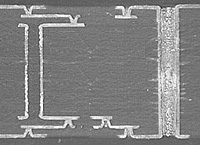

Acid oxidation process the MCT

Because multilayer PCBs reach the limits of technological process of manufacturing, with considerable added value, this implies very reliable processes

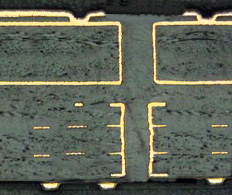

The revolution in the treatment of inner layers prior to multilayer lamination and bonding :

- Eliminates wedge voids and “Pink Rings”

- Suitable for horizontal and vertical lines

- A fast, economical and reliable

Acid oxidation the MCT technology : This treatment of the inner layers reduces the risk of delamination it also reduces the risk of Pink ring. It integrates into your current process, it is used in horizontal and vertical chain.

Acid oxidation the MCT technology : This treatment of the inner layers reduces the risk of delamination it also reduces the risk of Pink ring. It integrates into your current process, it is used in horizontal and vertical chain.

This is a fast process because short

An economic process: not reducer, easy for waste water treatment

IIt’s a reliable process: more resistant to manipulation, high adhesion (no pink ring).

And other benefits:

And other benefits:

Printed circuits Multilayer buried holes and blind holes• Operating temperatures moderate.

• Does not require micro-etching.

• Operates in horizontal or vertical chain.

• Low cost of equipment and use.

• High efficiency, small footprint.

• Low water use.

• Simple treatment of wastewater.

• Removes the reducer Black oxide.

• The treated copper is more resistant to handling.

• Excellent bond stresses: 7 to 16 N / cm